Like all boats, center consoles are a trade-off. While the open layout provides unencumbered room and flexibility, ideal for serious fishing, it offers little protection from the elements.

A hardtop or T-top certainly helps, but when the seas kick up or a storm brews, you just can’t beat weather curtains or full enclosures to keep you nice and dry. Of course, they’re not all created equal.

Whether or not curtains and enclosures provide the desired shelter is not the only issue; it’s also important to take into account how easily they stow, how long they last, and whether they hinder visibility at the helm. A number of marine canvas and fabrication shops offer different types and designs, and based on the intended use, available space and budget, they also offer guidance during the selection process. It helps to know that, essentially, what enclosures are made of determines how they behave, their longevity and the price.

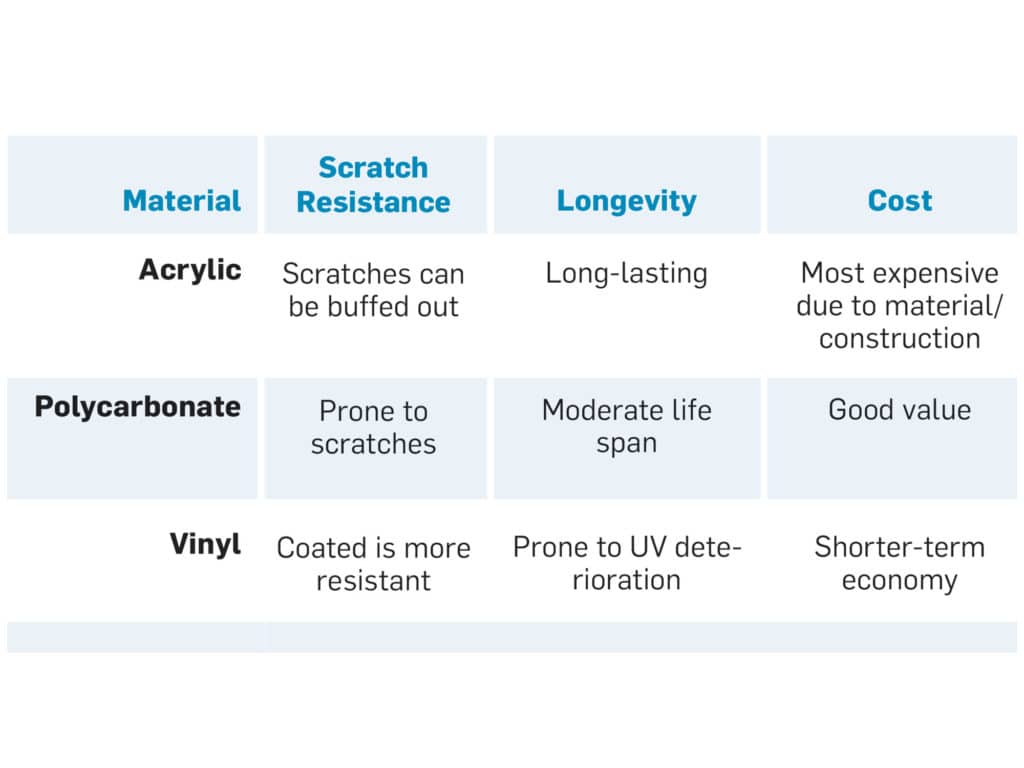

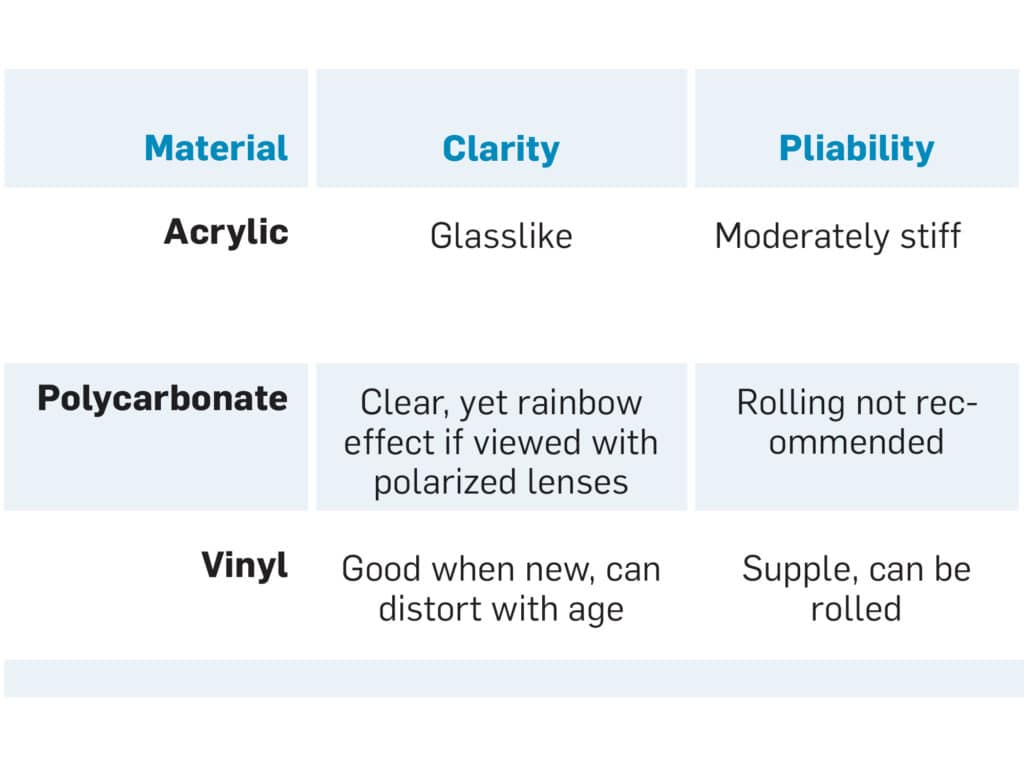

When it comes to materials, there are three basic choices: acrylic, polycarbonate and vinyl. Each has its pros and cons. Acrylic panels (common brands include Plexiglas, Lucite and Acrylite Plus) are made from plastic resins containing acrylic and methacrylic acids. It is the clearest material available, more so than normal glass, and is resistant to UV rays and many chemicals. Acrylic material cannot be sewn, however, so it requires special construction. Panels can also break when bent excessively, although some modified acrylic is more flexible.

Polycarbonate (Lexan, Hyzod and Aqua-Lite are among the top brands) is a petroleum-based thermoplastic known for its strength and resilience. It is softer than acrylic, but it scratches more easily and dimples become permanent, so rolling it (as one often does with curtains) is not recommended. Thinner panels can be sewn, but larger sheets tend to rattle. Another thing to consider is that the composition of polycarbonate produces a rainbow effect when viewed at an angle, especially through polarized sunglasses.

Clear vinyl, like isinglass, is made from flexible PVC. It’s a clear and haze-resistant material, although it expands and contracts with temperature changes, which often leads to distortion. Once vinyl is scratched, it can’t be polished or buffed clear again. Nevertheless, coated vinyl, like that made by Strataglass, is more scratch-resistant.

When asked about acrylic panels, Liderson says they become brittle with age or prolonged exposure to sunlight, which leads to cracking. The major advantages are their clarity and the ability to buff out scratches. Strataglass normally lasts from three to five years, he adds. Proper storage, cleaning and protective waxes are the keys to getting the maximum life out of any enclosures. Quality components and proven designs also prolong durability.“We only use premium YKK zippers when we fabricate enclosures, no matter the size of the boat. We also add flaps that cover the zippers so they are not exposed to the sun. That makes them last much longer,” Liderson says.

Flack is a big advocate of proper enclosure care. “Warm water and soap are your friends,” he says. “Salt and debris are what scratch most panels. If you keep them dirt- and dust-free, and regularly use a polish afterward, they’ll last for years. And never, ever use an alcohol-based cleaner on any enclosure material or you’ll ruin it.”

Choosing which enclosure material to use ultimately boils down to personal preference and budget. If the plan is a semipermanent installation, like side panels under a hardtop, acrylic or polycarbonate are usually the best choices. But if you want forward curtains that open when it’s hot and sunny, go with vinyl. Either way, find a reputable canvas shop for helpful suggestions and cost comparisons based specifically on your boat and style of fishing.

Andy Flack, project manager for Canvas Designers of Riviera Beach, Florida, an EZ2CY dealer, says the company outfits up to 200 center consoles per year, ranging from Hydra-Sports 53s down to 19-foot Key Wests. Coated acrylic is the material the company uses the most. “For rigid enclosures, we prefer coated acrylic. It’s more expensive, but it’s a superior product. It lasts longer, doesn’t crack or glaze, and it’s easier to clean. And if it does get scratched, it can be polished using a high-speed buffer,” Flack says.

He adds that the most popular designs for T-tops include an added vent for air circulation, but every boat installation is different and the costs vary accordingly. Flack explains installations can take up to 10 weeks during Florida’s busy winter season, while the summer wait time typically runs from four to six weeks.

American Marine Canvas & Upholstery in Miami, the company that originated the Bimini top, has been in business since 1922. Philip Liderson, the owner, explains that the company works with all three types of materials, but he prefers polycarbonate. “It’s the biggest bang for the buck. It can scratch, but adding a coating makes it more durable,” he says. “The clarity of polycarbonate is very good. It’s like looking through a car windshield; you don’t even see it. Polycarbonate can also be sewn, and we only use Gore-Tex thread, which won’t rot. So you’re looking at a life span of five to seven years.”

Smart Choice

Several factors come into play when choosing the proper material for curtains or an enclosure at the helm. Rigid materials are likely to require adequate designated storage space on the boat. The option of rolling curtains for storage demands less. Above all else, the installation must allow safe operation, which means top visibility where it’s crucial.