One of my best buddies, who is also a marine industry veteran, once proclaimed, “There are 1,000 ways to ruin an outboard, and I have seen all of them.”

I, too, have seen my share, some of them self-inflicted, I must admit.

Today’s four-stroke outboards are marvelous machines. They are quiet, efficient, powerful, easy to operate and offer years of trouble-free service. But you need to run them properly and care of them.

Many of the things that wreck outboard are easily avoidable by skippering your boat in a prudent manner and adhering to the manufacturer recommended maintenance schedule. Let’s look at six things that can break outboard motors, and how to prevent or fix them.

1. Corrosion Damage

Since we fish in salt water, corrosion is a common issue. The key is how you fight back with steps such as regularly replacing the sacrificial zincs as they wear away, flushing the engine cooling system with fresh water after trip, and keeping the lower unit(s) tilted clear of the water while the boat is docked. Do these things and other steps as recommended by manufacturer, and you help prevent corrosion damage. Do them not, and saltwater corrosion will have its way with your outboard.

2. Busted Skegs

Most skegs are bent or broken when the boat is on the trailer, and it most commonly occurs as the boat and trailer are being retrieved by a tow vehicle at the launch ramp and the helmsman forgets to tilt up the outboard(s). This can also lead to damaged propellers. Both are expensive to fix, so pay close attention to the position of the outboard before pulling up the ramp. Right after you turn it off, tilt it up so that the skeg and prop are clear of pavement.

3. Freeze Damage

This applies to boating anglers in northern climes where temperatures plummet in winter. Any water that pools in the cooling passages can freeze. As it does, it expands and can crack the outboard powerhead or gear case. To prevent this, pull the boat out of the water before winter sets in and store it on blocks or a trailer with the outboard(s) trimmed down completely to drain any residual cooling water. This also helps prevent rain water from collecting inside the exhaust barrel of the gearcase and later freezing.

4. Excessive Wear

Four-stroke outboards provides thousands of hours of service without excessive wear, but only if they are properly maintained. This means changing the engine oil, oil filter and gear lube at the manufacturer’s recommended intervals, which is usually every 100 hours. Unless you like spending money on repairs and new outboards, do not defer critical maintenance steps, as the viscosity of the oil and lube can break down with extended usage and turn acidic—factors that accelerate engine wear and result in reduced service life.

5. Overheating

This can damage an outboard’s cylinder walls, piston rings, water pump and more, and it’s almost always caused by lack of adequate cooling water. Causes include blockages in the cooling system due to corrosion, a malfunctioning thermostat, or a plastic bag wrapped around the water pickups on the lower unit. However, the cause is often the result of deferred maintenance of the water pump. Unless replaced as prescribed by manufacturer’s maintenance schedule, the vanes of the pump wear away or even break off. In either case, the pump might not effectively deliver cooling water to the engine. Also, parts of the broken vane can lodge in the cooling passages, creating blockages themselves. In either case, the engine can overheat. Fortunately, many of today’s outboards have early warning and fail-safe systems to forestall damage should the engine begin to overheat. Paid heed to the warnings.

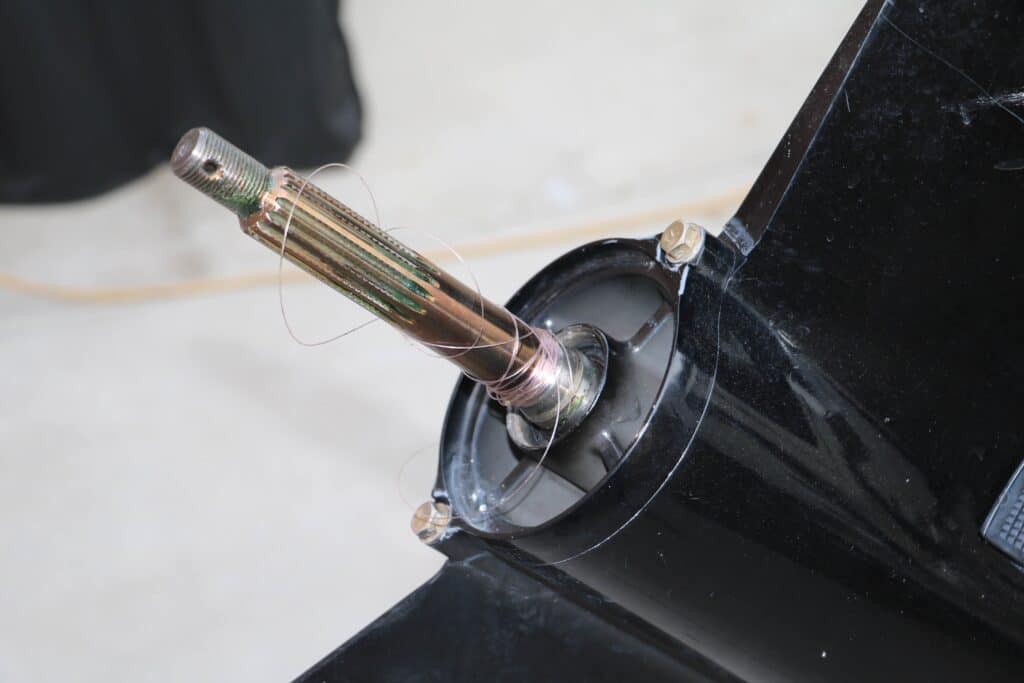

6. Damaged Gear Case Seal

Between the propeller and the gear case, there’s a seal for the prop shaft. It hardly ever fails, except when fishing line gets wrapped around the shaft in the area between the prop and the gear case, which is common. Left unattended while underway, the line winds its way under the working surface of the seal and cuts into the material, creating a leak. When this occurs, not only does gear lube leak out, water leaks in. In either case, it can seriously damage gear case components. Prevention is the key. Make sure crew members keep their fishing lines away from the props. If line does not get wrapped around the shaft, remove it as soon as possible, if not while out on the water, as soon as you return to port. If milky-looking gear lube leaks from the under the prop, you’re too late. Drain the lube immediately, pump in fresh lube and get the engine to a certified tech to replace the seal and pressure test the gear case before you run the engine again.